System Three

System Three General Purpose Epoxy

Contact the store for delivery options (250) 334-2886

Pickup currently unavailable at 2946 Kilpatrick Avenue

Tech Specs

System Three General Purpose Epoxy is our original product. It actually gave the company its name. From the founding of the company until just a few years ago it has been the workhorse of the product line. The system formulation, containing one resin and three curing agents or hardeners contains a significant amount of renewable materials. Long before "green” was in vogue the System Three General Purpose Epoxy System contained as much as 30% plant derived materials and has never contained any volatile organic compounds (VOC).

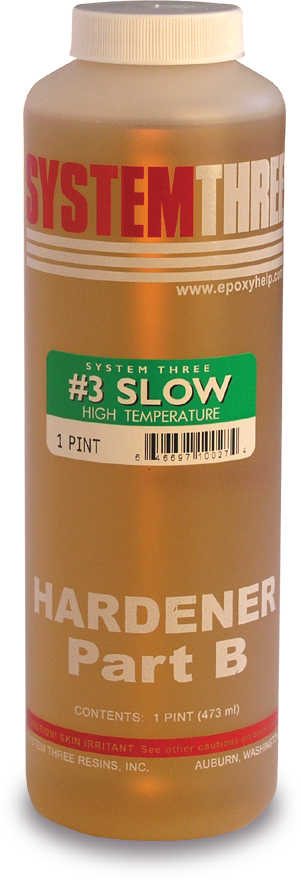

It has excellent pot life and cure-time control. When selecting a hardener, consider the minimum temperature expected during application and the desired working time. Combine different General Purpose Epoxy Hardeners to provide a continuous range of cure times. Refer to "The Epoxy Book” or the product datasheet to make a selection.

Recommended Uses:

System Three General Purpose Epoxy works great for wood construction and repair, for gel coat blister repair, and for general fiberglass repair. Use at a simple 2:1 volume ratio with any of the three hardeners. Use at temperatures as low as 35ºF with no limitations on humidity. The medium-low viscosity of System Three General Purpose Epoxy allows for use "as is" for coating and fiberglass work. Combine with different fillers to make adhesive, filleting and fairing compounds. Tired of the hassle of fillers? Use theSilverTip Marine Epoxy Seriesproducts.

- • Features a convenient 2:1 mixing ratio.

- • A solvent-free, unfilled, epoxy system.

- • Use for almost all epoxy applications.

- • Resin formulated for use with any of three hardeners.

- • Select hardener based on minimum temperatures expected during application and desired pot life.

- • Combine different System Three General Purpose Hardeners to provide a continuous range of cure times.

The GP resin system is naturally straw yellow to amber in color. Thinner films cure clear. We offer epoxy dispersed pigments in black, white, red, yellow, blue, brown, and green so you can make your own colored epoxy.